Long Lifespan Wheel Roller Coal Mineral Powder Charcoal Grinding Mixer Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | SINOLION mixer machine |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $1,000.00/sets >=1 sets |

|

Detail Information |

|||

| Applicable Industries: | Machinery Repair Shops, Other, Advertising Company | Showroom Location: | None |

|---|---|---|---|

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product | Warranty Of Core Components: | 1 Year |

| Core Components: | PLC, Motor, Pump | Condition: | New |

| Type: | Wheel Grinding Mixer | Motor Type: | AC Motor |

| Capacity(t/h): | 1-15 | Dimension(L*W*H): | Based On Different Model |

| Weight: | 0.9 KG | Warranty: | 1 Year |

| Product Name: | Wheel Roller Coal Mineral Powder Charcoal Grinding Mixer Machine | Installation: | Engineer's Guidance |

| Keywords: | Grinding Mixer Machine | Name: | Roller Mill |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Spare Parts Supplying: | Lifelong Provide |

| Application: | Mix And Grind | ||

Product Description

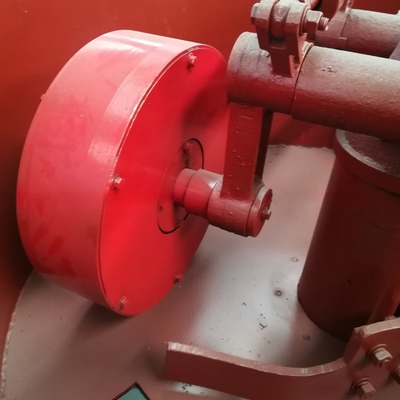

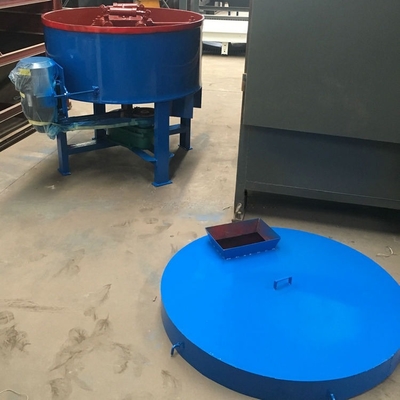

Wheel roller coal mineral powder charcoal grinding mixer machine

wheel roller mill roller griding mixer coal charcoal and mineral powder mixerbrief introduction

wheel roller mill is a machine designed based on merits of latest wheel mill and blending plant technology. it merging wheel mill and stirrong 2-in-1 type. with merits ofood stirring effect and high production effciency, notable energy saving effect, convenient installation and maintenance, good sealing performance, free environmental pollution, strong adaptability, with it's various technical indeses taking lead at hom, applicable to mixing partucle materials, such as fire clay, flt ash, taillings ore slag and moiding sand, extensively applied to singtering-free brick, steam-pressed brick, refractory materials and building materials.

![]()

![]()

Wheel roller mill main specifications and technical parameter

| Model | Barrel Dia. (mm) | Wheel Size (mm) | In Capacity (kg) | Stir time (min/time) | Spindle speed (r/min) | Power (KW) | Capacity (T/H) | Weight (T) |

| S110 | 1000 | 420*130 | 110 | 3-5 | 44 | 4 | 1-2.2 | 0.92 |

| S112 | 1450 | 590*117 | 200 | 3-5 | 34.7 | 7.5 | 2-4 | 1.6 |

| S114 | 1820 | 750*240 | 300-500 | 3-5 | 34 | 15 | 6-10 | 3.5 |

| S1120 | 2200 | 800*260 | 1000 | 3-5 | 30 | 37 | 10-15 | 5.6 |

![]()

Wheel roller mill working principle

After the machine is on work, the wheels will run continuously in its pan, the material is feed in the pan of a wheel roller mill with water as well as briquetting binder for grinding. Water can be fed into for mixing during the process to reach a certain moisture level for briquette making. Till the materials are grinded and mixed well, discharging hole can be opened to obtain all the materials within the wheel roller.

![]()

![]()

Wheel roller mill main Features

1). mix and grind at same time.

2). high production efficiency.

3). energy-saving.

4). easy to install and maintain.

5). good sealing property.

![]()

![]()