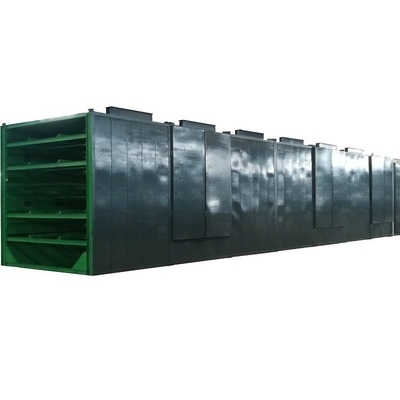

Customized Industrial Drying Oven for Coal Briquette Production Line and 4 Layers

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | SINOLION MACHINERY |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $120,000.00/sets >=1 sets |

|

Detail Information |

|||

| Type: | Drying Oven | Application: | Chemicals Processing, Plastics Processing, Food Processing, Briquette Processing, Briquette Processing, Ore,coal,charcoal |

|---|---|---|---|

| Condition: | New | Voltage: | 220-450V, 220v-450v |

| Power: | 5.5-37KW | Dimension(L*W*H): | 2 Meters Per Section |

| Key Selling Points: | Energy Saving | Warranty: | 1 Year |

| Weight (KG): | 3200 | Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Construction Works , Energy & Mining |

| Showroom Location: | None | Marketing Type: | New Product 2020 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Core Components: | Pump, Gear, Motor, Gearbox, Engine |

| Heating Method: | Gas Heating | Material: | Other |

| After-sales Service Provided: | Overseas Service Provided | Product Name: | Drying Machine |

| Heating Source: | Steam, Power, Hot Air | Color: | Customer's Request |

| Installation: | Engineer's Guidance | ||

Product Description

Product Description

♥High quality industrial drying oven used for coal briquette production line briquette dryer with 4 layers for sale

The Chain plate dryer is mainly used to dry large specific gravity material, This drying oven is one kind batch, tunnel type continuous production drying equipment, Mainly used to oven dry platy, strip and granular material, Heating source is power, steam and hot air, Main principle is to lay material on chain belt evenly ,then chain belt is dragged by transmission device to move forward and aft inside the machine, Hot air flow up and pass through the material, water vapor is discharged by exhaust vent , Finally reach to drying purpose

It is widely used in Metallurgy, Chemical industry, coal and refractories industries.

It is widely used in Metallurgy, Chemical industry, coal and refractories industries.

Main technical parameter

Model | FB-4-6 | FB-4-10 | FB-6-8 | FB-6-10 | FB-4-16 | FB-6-16 | |||||

Effective drying area(m2) | 43.2 | 72 | 86.48 | 108 | 115.2 | 172.8 | |||||

Flap length of every layer(m) | 6 | 10 | 8 | 10 | 16 | 16 | |||||

Flap layer No. | 4 | 4 | 6 | 6 | 4 | 6 | |||||

Effective width of flap | 1.8m | ||||||||||

Material average thickness | 10-80mm | ||||||||||

Operation temperature | 50-220℃ | ||||||||||

Steam Pressure | 0.2-0.8Mpa | ||||||||||

Drying capacity (kg water/h) | 210-260 | 360-432 | 432-518 | 540-648 | 576-691 | 864-1036 | |||||

Drying time (h) | 0.1-1 | 0.16-1.6 | 0.2-2 | 0.25-2.5 | 0.3-2.5 | 0.5-2.5 | |||||

Working Site

Packing & Delivery

High quality industrial drying oven used for coal briquette production line briquette dryer with 4 layers for sale

♥Standard export packing,

♥The loading port is Qingdao Port, also can be requested by customer. We have superior cargo agent to arrange the sea shipment for each client, competitive price, secure transportation.

♥All products will be processed to be rustproof and moisture proof before delivery.

♥20GP container or 40GP container Equipment is packed with plastic wrap or steel case, depends on machine weight.

♥Motor is packed with steel case or wooden case.

♥Control panel is packed with wooden case.

♥Loading container in factory.

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.♥The loading port is Qingdao Port, also can be requested by customer. We have superior cargo agent to arrange the sea shipment for each client, competitive price, secure transportation.

♥All products will be processed to be rustproof and moisture proof before delivery.

♥20GP container or 40GP container Equipment is packed with plastic wrap or steel case, depends on machine weight.

♥Motor is packed with steel case or wooden case.

♥Control panel is packed with wooden case.

♥Loading container in factory.

Company Profile

♥Zhengzhou Sinolion Machinery Co., Ltd. is a high-tech Company which professional manufacturing the production of briquette equipment, building material equipment, and mining machinery.

♥After 30years of development, Sinolion machinery is now setting up branches, integrating engineering, trade, research and development, production and sale to develop to be a large sized enterprise.

♥SINOLION machinery has modern standard workshops, as well as advanced technology and testing equipment. Extensively cooperating with coal research institutions and other research departments,

♥SINOLION machinery have continuously improved product values and performance. Now, 10,000-300,000 tons briquette production lines are renowned in domestic and foreign markets, and SINOLION machinery products have been exported to Indonesia, Kazakhstan, Vietnam, North Korea, Egypt and other countries and regions. It is ideal equipment for briquette mine power in the world market.

♥SINOLION machinery provides space planning and design, equipment installation and commissioning support

♥After 30years of development, Sinolion machinery is now setting up branches, integrating engineering, trade, research and development, production and sale to develop to be a large sized enterprise.

♥SINOLION machinery has modern standard workshops, as well as advanced technology and testing equipment. Extensively cooperating with coal research institutions and other research departments,

♥SINOLION machinery have continuously improved product values and performance. Now, 10,000-300,000 tons briquette production lines are renowned in domestic and foreign markets, and SINOLION machinery products have been exported to Indonesia, Kazakhstan, Vietnam, North Korea, Egypt and other countries and regions. It is ideal equipment for briquette mine power in the world market.

♥SINOLION machinery provides space planning and design, equipment installation and commissioning support

Customer Visit

FAQ

1.What kind of material can be dried by chain plate dryer machine?

Answer: Nearly all kinds of lump and chips material can be dried by our machine such as wood chips, leaves, coal briquettes, charcoal briquettes, iron pellets, etc.

2.What kind of fuel can be used with the briquette flap dryer machine?

Answer: Diesel, natural gas, coal, wood chips and other kind of fuel are OK.

3.What's the drying temperature of the mesh belt dryer?

Answer: Drying temperature of the dryer is adjustable. It varies from 50 to 350 °C.

4.How long will the briquettes stay in the briquette flap dryer machine?

Answer: Normally the drying time will be about 50-120 minutes.

5.Is the chain plate speed adjustable?

Answer: Yes, the chain plate speed is adjustable to make sure it can dry material with different moisture.

Answer: Nearly all kinds of lump and chips material can be dried by our machine such as wood chips, leaves, coal briquettes, charcoal briquettes, iron pellets, etc.

2.What kind of fuel can be used with the briquette flap dryer machine?

Answer: Diesel, natural gas, coal, wood chips and other kind of fuel are OK.

3.What's the drying temperature of the mesh belt dryer?

Answer: Drying temperature of the dryer is adjustable. It varies from 50 to 350 °C.

4.How long will the briquettes stay in the briquette flap dryer machine?

Answer: Normally the drying time will be about 50-120 minutes.

5.Is the chain plate speed adjustable?

Answer: Yes, the chain plate speed is adjustable to make sure it can dry material with different moisture.

Contact us

Want to Know more details about this product