Spare Parts for Coal Roller Briquetting Machine Screw Feeding System and Roller Skin

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Sinolion |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $1,200.00/pairs 1-1 pairs |

| Packaging Details: | All products will be processed to be rustproof and moisture proof before delivery. <br>20GP container or 40GP container <br>Equipment is packed with plastic wrap or steel box, depends on machine weight. <br>Motor is packed with steel box or wooden box. Con |

| Supply Ability: | 49 Set/Sets per Month |

|

Detail Information |

|||

| Type: | Briquette Machines | Applicable Industries: | Manufacturing Plant, Machinery Repair Shops, Retail, Energy & Mining |

|---|---|---|---|

| Weight (KG): | 100 | Showroom Location: | Canada, United States, Pakistan, Mexico, Russia, Thailand |

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty Of Core Components: | 1 Year |

| Core Components: | Roller | Condition: | New |

| Production Capacity: | 1-30t/h Briquette Machine | Motor Type: | AC Motor |

| Dimension(L*W*H): | Based On Model | Warranty: | 1 Year |

| Product Name: | Spare Parts Of Briquette Machine Screw Feeding System Rollers | Keyword: | Spare Parts Of Briquette Machine |

| Ball Shape: | Oval, Pillow And Oblate | Roller Diameter: | 290-1000mm |

| Roller Material: | 65Mn/9Cr2Mo | Applicable Material: | Coal, Charcoal, Carbon Black, Coke, Iron, Fluorite Powder Etc |

| Material Size: | Less Than 5mm | Material Moisture: | Less Than 18% |

| Spare Parts: | Supply Whole Life Of Briquette Press Machine | Service Life: | Supply Whole Life |

| Port: | Qingdao Shanghai Tianjin, Lianyungang,Guangzhou | ||

Product Description

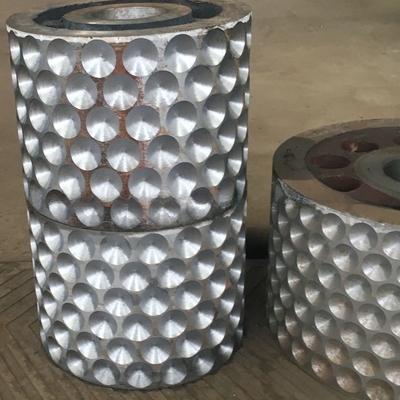

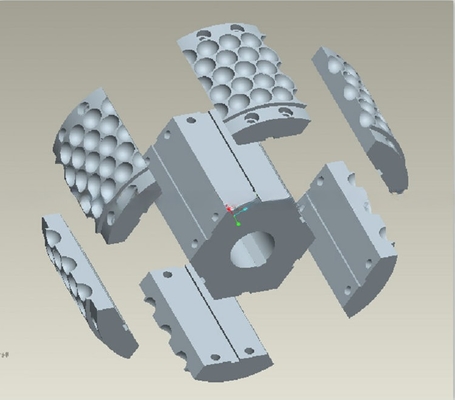

Spare parts of briquette machine spare included screw feeding system, roller skin

The ball press is an important molding equipment for many materials. As one of the core components of the ball press, the quality of the roller skin of the ball press seriously affects the production efficiency and quality of the ball press. It also affects the pressure of the ball press. Service life, frequent replacement of roller skins will certainly cause disassembly and wear of the ball press. Since the roller skin is so important, it is necessary to ensure its overall quality during processing and production. The staff of the roller skin manufacturer has organized the production process of the roller skin of the ball press for your reference. There are two methods for manufacturing the roller skin of the ball press machine, one is through casting and the other is forging.

![]()

1. Roller skin of casting and pressing ball machine

![]()

![]()

![]()

![]()

Standard export packing,Spare parts in wooden case,big machine loaded incontainer,large machines use nude packing,cover with plastic cloth.We export through Qingdao Port,also can be nominated by customer.We have superior cargo agent to arrange the sea shipment for each client,competitive price,secure transportation.

![]()

![]()

![]()