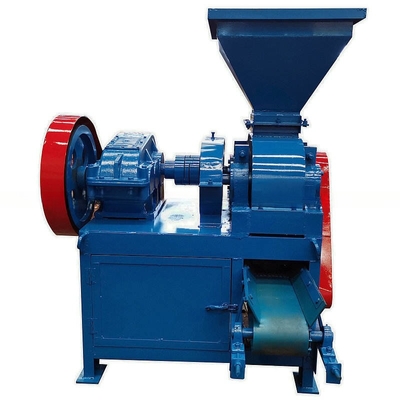

Industrial Briquette Making Machine for Coal and Refractories Industries Best Choice

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | SINOLION |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $2,200.00/sets >=1 sets |

|

Detail Information |

|||

| Type: | Briquette Machines | Applicable Industries: | Manufacturing Plant, Energy & Mining |

|---|---|---|---|

| Weight (KG): | 870 | Showroom Location: | None |

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty Of Core Components: | 1 Year |

| Core Components: | Motor | Condition: | New |

| Production Capacity: | 1-30t/h | Motor Type: | AC Motor |

| Warranty: | 1 Year | Raw Material: | Coal, Coal Powder, Coal Dust, Coal Breeze, Coal Fines |

| Keyword: | Briquette Machines | Voltage: | 380v 415v |

| Material Moisture: | Charcoal Less Than 50% | Color: | Client's Required |

| Application: | Fuel, Metallurgy,chemical Industry,coal And Refractories Industries | Installation: | Under Engineers Guidance Use Briquette Machine |

| Roller Diameter: | 290-1000mm | Briquette Shape: | Oval, Pillow And Oblate Iron Briquettes Etc |

| Material Size: | Less Than 5mm | ||

Product Description

China Best Supplier Industrial Briquette Making Machine

![]()

| Coal charcoal briquette press machine: Briquette machine can be used to press coal powder, charcoal powder,iron powder, coke, mineral powder, iron ore fines, metal dust, mill scale, iron oxide skin, carbon powder, slag, gypsum, tailing, sludge, kaolin clay, activated carbon, coke breeze and other powder and waste material .The briquette machine is widely used in refractory, power plants, metallurgy, chemicals, energy, transportation, heating, etc. industries. The final products have features of environmental friendly, easy to transport, improving the waste recycling, and good economic and social benefits. Feature of briquette machine: Briquette machine unique design is with lowest operating cost and very less maintenance for years makes it very successful & different from others. |

![]()

Feature of briquette machine:

1.Strong and stable structure,easy,operation and maintain easily.

2.High density,high strength &high hardness briquettes.

3.High briquetting ratio.

![]()

China best supplier industrial briquette making machine :

| Model | Reducer | Roller size | Power (Kw) | Yield (t/h) | Roller Material | Roller pressure (t/cm) |

| XM290 | ZQ300 | Φ290 | 5.5 | 0.8-2 | 65Mn | 1 |

| XM360 | ZQ350 | Φ360 | 7.5 | 2-3.5 | 65Mn/9Cr2Mo | 1 |

| XM400 | ZQ400 | Φ400 | 11 | 4-5 | 65Mn/9Cr2Mo | 1 |

| XM430 | ZQ400 | Φ430 | 11 | 5-7 | 65Mn/9Cr2Mo | 1-2 |

| XM500 | ZQ500 | Φ500 | 18.5-30 | 6-8 | 65Mn/9Cr2Mo | 1-2.5 |

| XM650 | ZQ650 | Φ650 | 22 | 8-12 | 65Mn/9Cr2Mo | 1-2.5 |

| XM750 | ZQ750 | Φ750 | 30-75 | 12-18 | 65Mn/9Cr2Mo | 1-2.5 |

| XM850 | ZQ850 | Φ850 | 55-90 | 18-25 | 65Mn/9Cr2Mo | 1-2.5 |

| XM1000 | ZQ1000 | Φ1000 | 75-130 | 25-30 | 65Mn/9Cr2Mo | 2-2.5 |

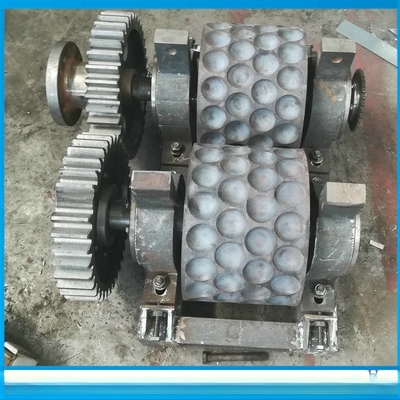

Working Principle

| Roller press works with two close rotating rollers at the same speed but with opposite direction. The two rollers, with the same width and diameter, have holes on the surface. When they move, the same two holes on the different roller will coincide at the intersection of the midline and the briquette will be pressed there. With different pressure requirement, roller press can be designed to several types. A normal roller press will use a wedge iron to fix the movable roller as it works on a low pressure. The hydraulic pump station is also can be used to fix the roller and supplies a much bigger but flexible support to the roller to work stable on big pressure. |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Ms. Max Zhang

Tel/Wechat/Whatsapp: +86-17734780472

| Sawdust Briquette Machine | Extruder Machine | Chain Plate Dryer |