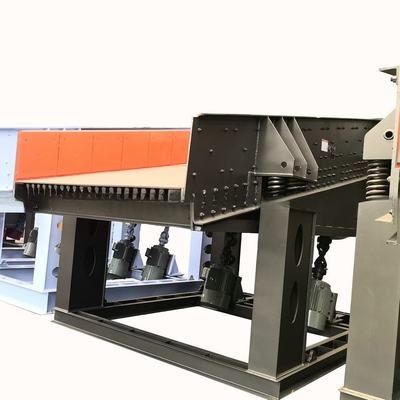

GZD Series Vibratory Jaw Crusher Feeder for Sand Making Plant Supply Manual Included

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Sinolion |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $5,000.00/sets >=1 sets |

|

Detail Information |

|||

| Applicable Industries: | Energy & Mining | Showroom Location: | None |

|---|---|---|---|

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | Ordinary Product | Warranty Of Core Components: | 1 Year |

| Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump | Condition: | New |

| Application: | Ore, Coal, Stone, Quarry, | Power Type: | Electric |

| Capacity(t/h): | 30-500 Tons Per Hour | Dimension(L*W*H): | As Per Different Model |

| Weight: | 2798 KG | Warranty: | 24 Months Excluding Spare Parts |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Installation Angle: | 0°-10° |

| Max Feed Size: | 750mm | Grizzly Spacing: | As Request |

| Installation: | Supply Manual To Guide User Or Under Engineer's Guide | Wearing Parts: | Spring |

| After Sale Service: | Life-long Service | Spare Parts Supply: | Lifelong Time |

| Motor Brand: | Siemens Or As Request | ||

Product Description

Vibratory Jaw Crusher Feeder Application Field:

Vibratory jaw crusher feeders are widely used in mining, building-material, silicate andchemical industry in the crushing and screening plants.In the Sand-Stone production line, vibrating feeder can send materials to crusher evenly and continuously and at the same time, it can screen materials roughly.Vibrating feeder can be used in these areas such as metallurgical industry, coal mining industry, mining-selecting, building, chemical and grinding industry, etc.

Vibratory Jaw Crusher Feeder Advantages:

Vibratory feeder enjoys simple structure, stable vibrating, even feeding, good continuous performance, adjustable excitation force, etc. Its flow rate can be conveniently changed and controlled.

Vibratory feeder adopts eccentric block as the excitation source and features low noise, low energy consumption, good adjusting performance, and no material splashing.

Closed type vibratory feeder can prevent the pollution of dust.

The pressure caused by the material to the groove should be reduced to the greatest extend. The effective discharge opening should be smaller than the one quarter of the groove width. The flow rate should be controlled within 6-18m/min.

For feeding materials with a large quantity, a fender with enough height should be installed at the outlet. This fender should not be fixed to the feeder since it will affect the performance of the machine.

Vibratory jaw crusher feeder techinical parameters:

| Model | Max feed size (mm) | Capacity (t/h) | Motor Power (kw) | Installation angle (°) | Weight (kg) | Dimension (mm) |

| GZD-600x3000 | 300 | 30-80 | 2.2x2 | 10 | 2798 | 3000x1310x780 |

| GZD-850x3000 | 400 | 80-120 | 1.5x2 | 10 | 3607 | 3110x1800x1600 |

| GZD-950x3800 | 500 | 120-200 | 2.2x2 | 5 | 3980 | 3850x1950x1630 |

| GZD-1100x4200 | 580 | 200-300 | 3.0x2 | 5 | 4170 | 4400x2050x1660 |

| GZD-1100x4900 | 580 | 300-400 | 3.5x2 | 5 | 4520 | 5200x2050x1700 |

| GZD-1300x4900 | 650 | 400-500 | 5.5x2 | 5 | 5200 | 5200x2350x1750 |

| ZSW-380x95 | 500 | 96-160 | 11 | 0 | 4082 | 3920x1640x1320 |

| ZSW-490x110 | 630 | 120-280 | 15 | 0 | 5352 | 4980x1830x1320 |

| ZSW-490x130 | 750 | 400-560 | 22 | 0 | 7800 | 4980x2580x2083 |

![]()

![]()