High Manganese Steel Concrete Jaw Crusher for Mobile Gold Ore Crushing in Sri Lanka

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Sinolion |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $1,200.00/sets >=1 sets |

|

Detail Information |

|||

| Applicable Industries: | Energy & Mining | Showroom Location: | Viet Nam, Philippines, Indonesia, India, Thailand, Sri Lanka, None |

|---|---|---|---|

| Condition: | New | Type: | Jaw Crusher |

| Application: | Chemical Industry, Stone, Ore, Glass, | Motor Type: | AC Motor |

| Capacity(t/h): | 1-500t/h | Dimension(L*W*H): | As Per Different Model |

| Weight: | 800 KG | Warranty: | 24 Months Excluding Spare Parts |

| Marketing Type: | New Product 2020 | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Core Components: | Motor | Key Selling Points: | High Manganese Steel |

| Model: | PE Series Coal Jaw Crusher Machine | Installation: | Supply Manual And Send Engineer To Guide User |

| Feeding Size: | 0-1020mm | Discharge Size: | 0-300 |

| Jaw Plate Material: | High Manganese | Driving Type: | Diesel Engine Or Motor |

| Wearing Parts: | Jaw Plates | Product Name: | Small Jaw Crusher For Sale |

| Price: | Negotiable | Color: | Yellow, White, Red, Blue, Gray( Or As Client Request) |

Product Description

Introduction of jaw crusher:

Jaw crusher is one of the most popular equipment in mine industry production. It is mainly used in all kinds of materials with middle crushing or coarse crushing, and the crush resistance below 320MPa. Jaw crusher has the features of high crushing rate, simple structure, stable operation, easy maintenance and low operation cost. Jaw crusher is derived by motor through the motors wheels; the eccentric shaft is derived by the fangled belt and slot wheel to make the movable jaw plate move by a regulated track. Therefore, the materials in the crushing cavity composed of fixed jaw plate, The movable jaw plate and cheek plate can be crushed and discharged through the discharging opening.

![]()

Coal jaw crusher working principle:

Motor drives belt and belt pulley, makes moving jaw up and down through eccentric shaft. When the moving jaw is up, the angle between lining plate and moving jaw becomes large, and this will push moving jaw plate close to the fixed jaw plate. During this process, the material is crushed and ground, thus the crushing will be done.

When the moving jaw is down, the angle between lining plate and moving jaw becomes small, the moving jaw plate will leave the fixed jaw plate on account of the effect of pulling bar and spring, and then the crushed material will be discharged from the lower opening of the crushing room.

With the motor continuously rotating and the material periodically crushed and discharged by the crusher, the mass production can be realized.

Primary jaw crusher technical parameters:

| Model | max feed size (mm) | Discharge size (mm) | Capacity (t/h) | Power (kw) | Weight (T) |

| PE-150×250 | 125 | 10-40 | 1-3 | 5.5 | 0.8 |

| PE-200×300 | 180 | 20-70 | 2-8 | 11 | 1.4 |

| PE-250×400 | 210 | 20-80 | 5-20 | 15 | 3 |

| PE-400×600 | 350 | 40-100 | 15-60 | 30 | 6.5 |

| PE-500×750 | 425 | 50-100 | 40-110 | 55 | 11.3 |

| PE-600×900 | 480 | 65-160 | 90-150 | 75 | 17.625 |

| PE-750×1060 | 630 | 80-160 | 100-250 | 90-110 | 27.5 |

| PE-900×1200 | 750 | 95-165 | 120-300 | 110-160 | 52 |

| PE-1000×1200 | 850 | 110-260 | 180-350 | 110-160 | 57 |

| PE-1200x1500 | 1020 | 150-300 | 300-500 | 180-220 | 100 |

Secondary jaw crusher technical parameters:

| Model | max feed size (mm) | Discharge size (mm) | Capacity (t/h) | Power (kw) | Weight (T) |

| PEX-150×750 | 120 | 8-25 | 10-40 | 15 | 3.5 |

| PEX-250×750 | 210 | 12-25 | 15-50 | 30 | 5.5 |

| PEX-250×1000 | 210 | 12-50 | 30-95 | 37 | 6.37 |

| PE-350×750 | 300 | 15-50 | 20-50 | 30 | 6.5 |

| PE-300×1300 | 250 | 20-90 | 45-130 | 75 | 11 |

| PE-600×900 | 480 | 65-160 | 90-150 | 75 | 17.625 |

Jaw crusher structure:

![]()

Portable diesel engine jaw crusher pe250x400:

![]()

![]()

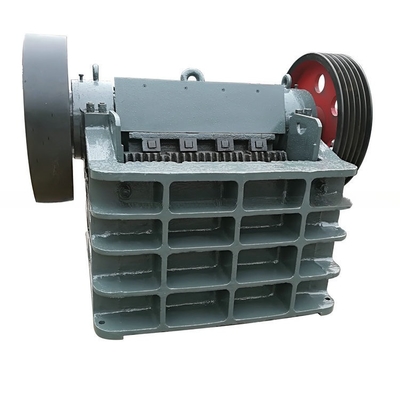

Finished jaw crushers:

![]()

![]()

Jaw crusher spare parts: jaw plates, spring, fly wheels, etc.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Question 1: What’s the delivery time after I pay the deposit ?

Answer: We will delivery the goods within 10-15 working days after receipt of the prepayment.

Question 2: Is mineral samples analysis available?

Answer: Sure, we supply samples analysis service for free. After the testing, we will give you the reasonable flow chart, suitable solution and equipment selection.

Question 3: Do you have client in my country?

Answer: Our products have exported to Malaysia, Indonesia, the Philippines, Vietnam, Myanmar, Korea, Singapore, Thailand, Mongolia, Ghana, Sudan, Serbia, Kazakhstan, Canada, Nigeria, Australia, Chile, Brazil, Columbia, Ecuador, Peru, Bolivia, etc

Question 4: How long of your machine quality guarantee terms ?

Answer: Quality guarantee time is one year(wearing parts excluded).

![]()