Multi-Deck YK Series Circular Vibrating Screen for Quarry Soil Classifier and Sorting

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Sinolion |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $1,500.00/sets >=1 sets |

| Packaging Details: | All products will be processed to be rustproof and moisture proof before delivery. <br>20GP container or 40GP container. <br>Equipment is packed with plastic wrap or steel case, depends on machine weight. <br>Motor is packed with steel case or wooden case. |

| Supply Ability: | 50 Set/Sets per Month vibrating sieve shaker screener |

|

Detail Information |

|||

| Applicable Industries: | Energy & Mining | Showroom Location: | Indonesia, Mexico, Japan, Malaysia |

|---|---|---|---|

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2021 | Warranty Of Core Components: | 1 Year |

| Core Components: | Gearbox | Condition: | New |

| Type: | Circular | Application: | Ore, Stone, Sand, Glass, Mulch, Organics, Topsoil, Bark |

| Voltage: | 380V/415V/440V( As Client Request) | Dimension(L*W*H): | As Per Different Model |

| Weight: | 1400 KG | Warranty: | 18 Month Excluding Spare Parts |

| Product Name: | Circular Vibrating Screen For Pebbles Soil Screening Classifier | Model: | YK Series Boulder Vibrating Screen |

| Installation: | Supply Manual To Guide User | Capacity: | 10-700 Tons Per Hour |

| Feeding Size: | Less Than 300mm | Discharge Size: | 4-80mm |

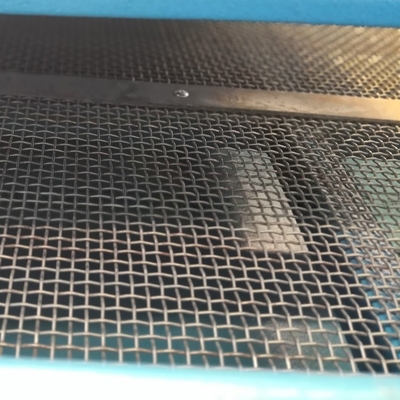

| Screen Deck Number: | 1-5 Layers | Mesh Material: | Manganese Wire Woven Or Stainless Steel Wire Woven |

| Color: | Yellow, White, Red, Blue, Gray( Or As Client Request) | Port: | Qingdao, Tianjin, Lianyungang, Shanghai, Guangzhou( As Client Request) |

Product Description

Boulder vibrating screen introduction:

YK Series boulder vibrating screen can be used to separate minerals into various sizes for further processing in crusher. It incorporates a vibrator, eccentric block, mesh, spring, triangular belt and motor and is used for discharging bulky goods, sand, gravel, coal and coke from hopper to crusher. We can design and supply all ranges of vibrating screens according to the capacity and requirement.

Boulder vibrating screen working principle:

Boulder vibrating screen mainly consists of the eccentric block vibrator, screen box, motor, and supportive device. Through the flexible coupling, the motor drives the eccentric block of the vibrator rotate at high speed, generating the centrifugal force, and then causing the screen box do circular movement by the amplitude. After that, the materials in the slope screen surface will be cast continuously by the force generated from the screen box, then realizes the purpose of classifying.

![]()

Boulder vibrating screen specifications:

| Model | screen deck | installation slope(°) | screen size(mm) | feeding size(mm) | capacity (t/h) | motor power (kw) | weight (kg) |

| YK1230 | 1 | 15 | 4-50 | ≤300 | 10-75 | 5.5 | 1468 |

| 2YK1230 | 2 | 15 | 4-50 | ≤300 | 13-78 | 5.5 | 2253 |

| 3YK1230 | 2 | 15 | 4-50 | ≤300 | 15-80 | 7.5 | 2978 |

| 4YK1230 | 3 | 15 | 4-50 | ≤300 | 17-90 | 7.5 | 3982 |

| YK1235 | 1 | 15 | 4-50 | ≤300 | 20-150 | 5.5 | 1729 |

| 2YK1235 | 2 | 15 | 4-50 | ≤300 | 20-150 | 5.5 | 2474 |

| 3YK1235 | 2 | 15 | 4-50 | ≤300 | 22-150 | 7.5 | 3158 |

| 4YK1235 | 4 | 15 | 4-50 | ≤300 | 22-150 | 7.5 | 4160 |

| 2YK1545 | 2 | 20 | 5-50 | ≤300 | 22-150 | 11 | 5308 |

| 3YK1545 | 3 | 20 | 5-50 | ≤300 | 50-180 | 15 | 5915 |

| 4YK1545 | 4 | 20 | 5-50 | ≤300 | 50-180 | 15 | 7126 |

| 2YK1554 | 2 | 20 | 5-50 | ≤300 | 50-200 | 15 | 5284 |

| 3YK1554 | 3 | 20 | 5-50 | ≤300 | 56-200 | 15 | 6186 |

| 4YK1554 | 4 | 20 | 5-50 | ≤300 | 56-250 | 18.5 | 7284 |

| 2YK1854 | 2 | 20 | 5-80 | ≤300 | 56-300 | 18.5 | 5826 |

| 3YK1854 | 3 | 20 | 5-80 | ≤300 | 60-400 | 18.5 | 7368 |

| 4YK1854 | 4 | 20 | 5-80 | ≤300 | 80-400 | 22 | 8281 |

| 2YK1860 | 2 | 20 | 5-80 | ≤300 | 60-400 | 22 | 6195 |

| 3YK1860 | 3 | 20 | 5-80 | ≤300 | 80-400 | 22 | 7613 |

| 4YK1860 | 4 | 20 | 5-80 | ≤300 | 90-500 | 30 | 8650 |

| 2YK2160 | 2 | 20 | 5-80 | ≤300 | 100-720 | 22 | 6856 |

| 3YK2160 | 3 | 20 | 5-80 | ≤300 | 100-720 | 30 | 9112 |

| 4YK2160 | 4 | 20 | 5-80 | ≤300 | 100-720 | 30 | 10405 |

![]()

![]()

![]()

1. Pre-sale service:

1) Sinolion will provide production line design, quotation sheet, working sites video, machinery photos, sample testing(gold ore, tin ore , iron ore, tungsten processing in laboratory).

2) Welcome to visit us at any time, we will pick you up.

2. Sale service:

1) Keep clients updated when our company gets advance payment.

2) Confirm production details with clients.

3) Take photos and send all pictures to customers during production.

4) Inspection and testing the product before delivery;

5) Clients are welcome to inspect the equipment when the equipment are ready to delivery.

6) logistics service if needed.

3. After Sale service:

1) Provide foundation drawing to the clients for installation.

2) Besides, our engineers are available to help with installation and workers training.

3) Repairing and maintenance if any problem during the warranty.

4) Spare parts and wearing parts will be offered with production cost in 10 years.

![]()

Question 1: What’s the delivery time after I pay the deposit ?

Answer: We will delivery the goods within 10-15 working days after receipt of the prepayment.

Question 2: Is mineral samples analysis available?

Answer: Sure, we supply samples analysis service for free. After the testing, we will give you the reasonable flow chart, suitable solution and equipment selection.

Question 3: Do you have client in my country?

Answer: Our products have exported to Malaysia, Indonesia, the Philippines, Vietnam, Myanmar, Korea, Singapore, Thailand, Mongolia, Ghana, Sudan, Serbia, Kazakhstan, Canada, Nigeria, Australia, Chile, Brazil, Columbia, Ecuador, Peru, Bolivia, etc

Question 4: How long of your machine quality guarantee terms ?

Answer: Quality guarantee time is one year(wearing parts excluded).