Low Failure Rate and High Capability 2200 KG Food Beverage Integrated Sorting Machine

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Sinolion |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 unit |

|---|---|

| Price: | $4,000.00/sets >=1 sets |

|

Detail Information |

|||

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Beverage Shops | Showroom Location: | Canada, United States, Germany, Brazil, Indonesia, Mexico, Russia, Australia |

|---|---|---|---|

| Video Outgoing-inspection: | Provided | Machinery Test Report: | Provided |

| Marketing Type: | New Product 2020 | Warranty Of Core Components: | 2 Years |

| Core Components: | Gearbox, Motor | Condition: | New |

| Type: | Other | Application: | Other, Glass, Mulch, Organics, Bark, MSW, Plaster Board |

| Voltage: | As Client Request | Dimension(L*W*H): | As Per Different Model |

| Weight: | 2200 KG | Warranty: | 24 Months |

| Product Name: | Garbage Screening Machine Integrated Sorting Machine Failure Rate | Screen Material: | Steel Bar, Steel Plate, Manganese Steel Wire Woven, Stainless Steel |

| Power: | 3-45KW | Dimension: | 5600x2015x2010mm |

| Capacity: | 1-200 Tons Per Hour | Feeding Size: | Less Than 300mm |

| Discharge Size: | Less Than 6mm Or As Request | Keyword: | Waste Garbage Recycling Machine |

| Name: | Waste Treatment Machinery | ||

Product Description

Garbage Screening Machine Integrated Sorting Machine Failure Rate Low Processing Capacity

![]()

![]()

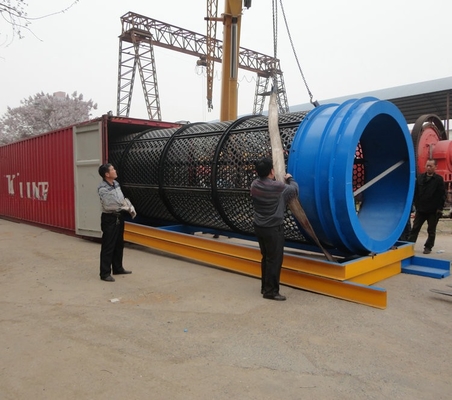

Shaftless trommel screen working principle:

Due to the turning and rolling of the material in the screen drum, the material stuck in the screen hole can be ejected to prevent the screen hole from being clogged. GTS series shaftless trommel screen machine mainly consists of motor, gearbox, screen drum, frame, sealing cover, inlet and outlet. The screen drum is mounted obliquely on the frame. The motor is coupled to the drum unit via a coupling through a reducer to drive the screen drum unit to rotate about its axis. After the material enters the screen drum, due to the tilting and rotation of drum screen, the material on the screen surface is turned over and rolled, so that the qualified material (the product under the sieve) is discharged through the screen, and the unqualified material (the product on the sieve) ) is discharged through the end of the screen drum.![]()

Application:munlcpal solid waste,construction waste,stone,compost,wood chips,sawdust,soil,coal,river sand,refractory materials,chemiacal,etc

| Model | Drum size (m) | Drum inclination (°) | Drum speed (r/min) | Mesh size (mm) | Max feeding size (mm) | capacity (m³/h) | Motor power (kw) |

| GTS820 | Φ0.8×2 | 6-10 | 32 | 2-20 | Mesh size×2.5 | 7-30 | 3 |

| GTS830 | Φ0.8×3 | 6-10 | 32 | 2-20 | Mesh size×2.5 | 8-50 | 3 |

| GTS1020 | Φ1×2 | 6-10 | 25 | 2-20 | Mesh size×2.5 | 10-60 | 4 |

| GTS1030 | Φ1×3 | 6-10 | 25 | 2-20 | Mesh size×2.5 | 11-80 | 4 |

| GTS1230 | Φ1.2×3 | 6-10 | 20 | 2-20 | Mesh size×2.5 | 12-100 | 5.5 |

| GTS1240 | Φ1.2×4 | 6-10 | 20 | 2-20 | Mesh size×2.5 | 14-120 | 5.5 |

| GTS1530 | Φ1.5×3 | 6-10 | 17 | 2-20 | Mesh size×2.5 | 16-120 | 5.5 |

| GTS1540 | Φ1.5×4 | 6-10 | 17 | 2-20 | Mesh size×2.5 | 18-150 | 7.5 |

| GTS1550 | Φ1.5×5 | 6-10 | 17 | 2-20 | Mesh size×2.5 | 20-180 | 11 |

| GTS1560 | Φ1.5×6 | 6-10 | 17 | 2-20 | Mesh size×2.5 | 22-200 | 11 |

| GTS1850 | Φ1.8×5 | 6-10 | 14 | 2-20 | Mesh size×2.5 | 24-220 | 15 |

| GTS1860 | Φ1.8×6 | 6-10 | 14 | 2-20 | Mesh size×2.5 | 26-240 | 15 |

| GTS2050 | Φ2×5 | 6-10 | 12 | 2-20 | Mesh size×2.5 | 50-600 | 22 |

| GTS2080 | Φ2×8 | 6-10 | 12 | 2-20 | Mesh size×2.5 | 80-700 | 22 |

| GTS2260 | Φ2.2×6 | 6-10 | 10 | 2-20 | Mesh size×2.5 | 100-800 | 30 |

| GTS2280 | Φ2.2×8 | 6-10 | 10 | 2-20 | Mesh size×2.5 | 120-850 | 30 |

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()